„Der Kunde wünscht nicht die Erklärung, sondern die Lösung Seines Problems.“

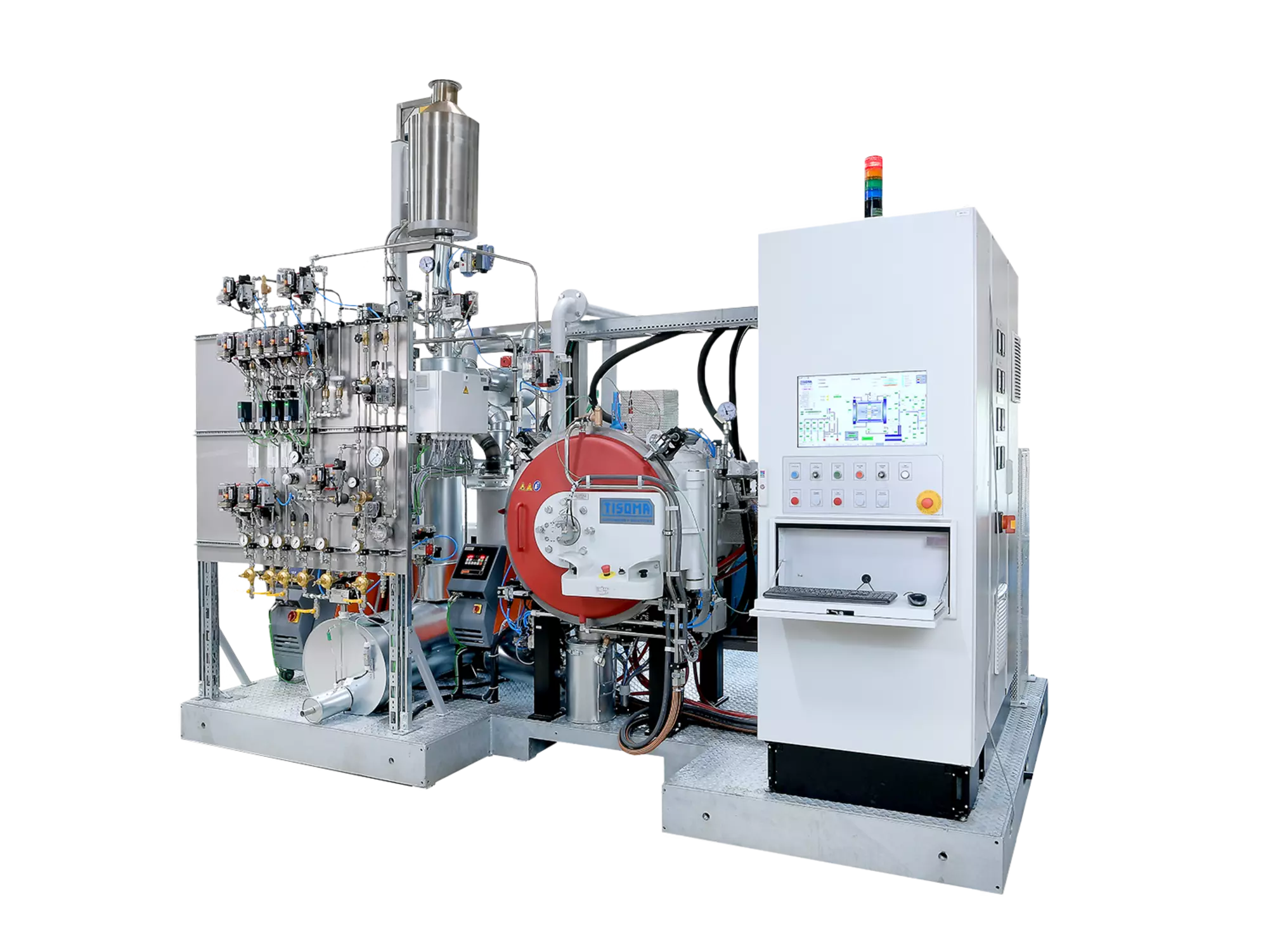

Nach diesem Motto konstruieren und bauen wir seit 1996 unter dem Namen TISOMA Anlagenbau und Vorrichtungen GmbH Maschinen und Anlagen.

Dabei ist es uns wichtig das Problem nicht zu beschreiben, sondern schnell und gezielt eine Lösung zu erarbeiten.

Durch Effektivität und Zielstrebigkeit bereits in der Projektierung und Planung der Projekte gelangen wir gemeinsamen mit IHNEN zum Ziel.

16 Länder – Tendenz steigend.

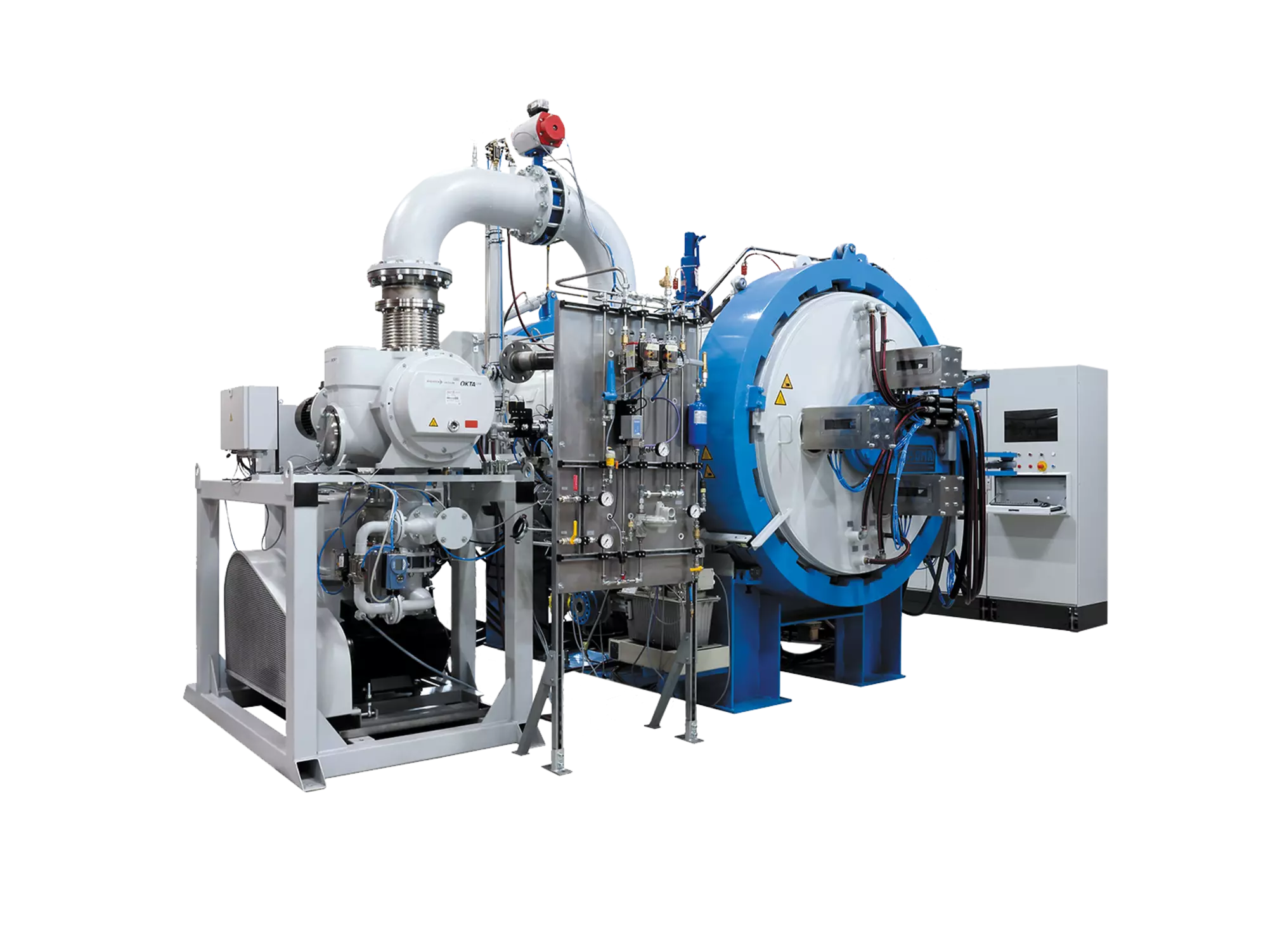

Wir sind ein international agierendes Unternehmen. Unsere Anlagen stehen in 16 verschiedenen Ländern verteilt in Europa, Asien und Afrika. Durch einzigartige Produktmerkmale stehen unsere Anlagen im Fokus verschiedenster Interessenten, sodass wir unsere Bekanntheit weltweit stets steigern.

Wir haben für jeden Anspruch eine Lösung. Auch für Ihren.

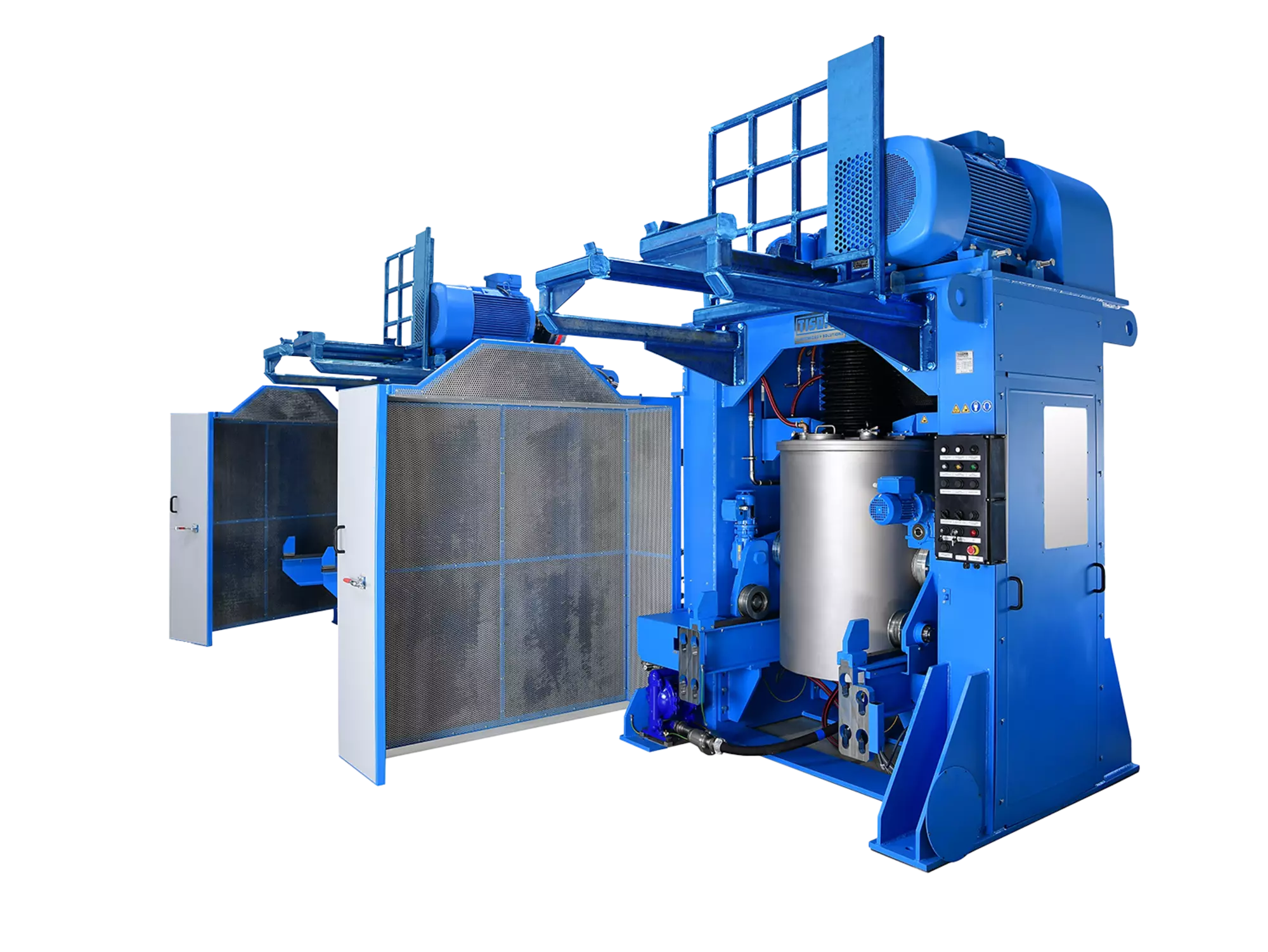

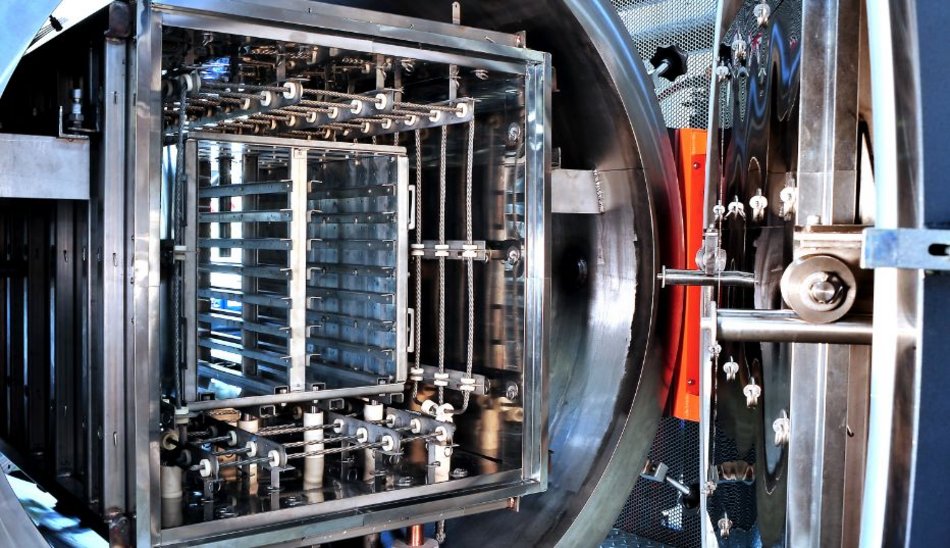

Im Mittelpunkt unserer Arbeit stehen die Anforderungen und Wünsche unserer Kunden. Nach dem Konzept „customized solutions“ erhalten SIE keine Standard-Maschinen, sondern Anlagen, welche exakt auf Ihren Prozess abgestimmt und angepasst wurden.

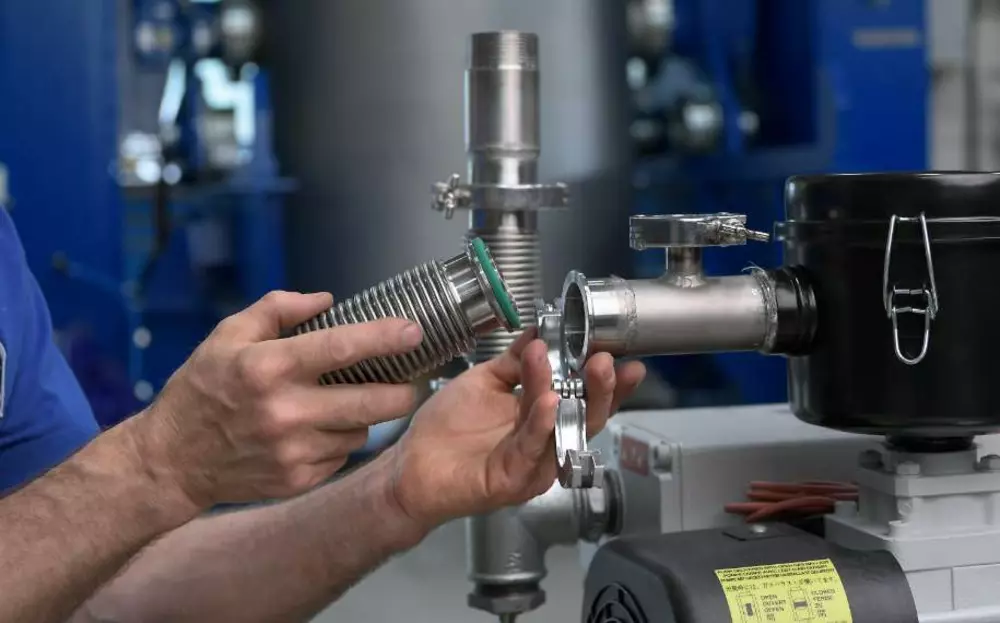

Für unser hauseigenes Engineering-Team und unsere hochqualifizierten Mitarbeiter gibt es nahezu keine Grenzen all Ihren Wünschen und Ansprüchen gerecht zu werden.

Seien Sie nicht mit dem Standard zufrieden und starten Sie IHR individuelles Projekt mit uns.