Attritors

Our attritors are used for grinding and homogenizing a wide variety of material suspensions. The machines are primarily used in the hard metal, ceramic and powder industries.

A vertically arranged agitator rotates in a container equipped with grinding media (grinding balls). The high kinetic energy of the agitator and the huge amount of contact points of the grinding bodies ensure rapid grinding, homogenization and mixing of the raw materials.

The grinding bodies are selected according to the process (diameter, shape, material). The processing of very hard and abrasive raw materials is also possible.

Further technical features:

- Explosion-proof version (ATEX) possible

- Simple manual machine operation up to modern Siemens system controls and process visualizations.

- Double-walled grinding container for heating or cooling the suspension

- Pumping around the suspension (circulation) during the grinding process

- Container inner jacket made of stainless steel or with application-specific lining/coating

- Wear protection for the agitator

- Soundproofing insulation (optional)

- Additional equipment for powder handling and filling the machine

- Integration into higher-level production systems on request

Our sizes:

Attritor | Batch size (process liquid + raw material) |

RMK 250 | max. 250 kg |

RMK 350 | max. 350 kg |

RMK 500 | max. 500 kg |

RMK 750 | max. 750 kg |

RMK 1000 | max. 1000 kg |

further sizes - on request

Dry grinding processes - on request.

Laborator Attritors / Small size Attritors

Our attritors are also available as small or laboratory systems.

For small production quantities or for research and development.

Product advantages:

- Powerful, rapid grinding and homogenization of raw materials

- Explosion-proof version (ATEX) possible

- variable agitator speed for experiments up to 350 rpm

- Double-walled stainless steel container for heating or cooling the suspension

upon request with application-specific lining/coating on the inside

- Circulation system

- Additional equipment for powder handling and filling the machine

- Plug and Work – system by using plug connections for easy start up

- Wear protection for agitator

Our standard sizes:

Attritor | Batch size ( process liquid + raw material ) |

RMK 1 | max. 1 kg |

RMK 10 | max. 10 kg |

RMK 25 | max. 25 kg |

RMK 50 | max. 50 kg |

*individual machine configurations and equipment on request

Ball mills

The ball mill or drum mill is a machine for the classic crushing, grinding and homogenization of raw materials.

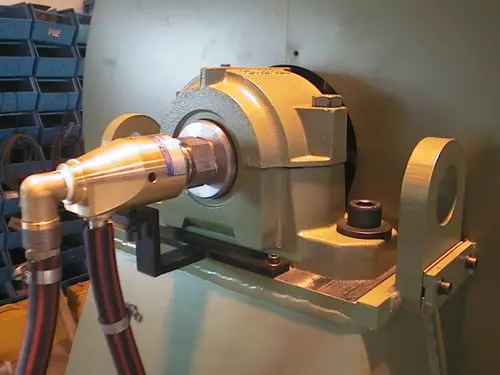

The ball mill consists of a horizontal cylindrical drum that is supported on both sides. The grinding chamber is filled with grinding bodies, usually grinding balls, and the material to be ground (raw materials and process liquid).

The rotation of the drum and the targeted movement of the grinding media generates kinetic energy, which acts on the material to be ground in the form of impact, friction and shear forces.

The material can be cooled or heated during the process via the double wall of the container. The ball mills are suitable for batch processes. Filling/emptying takes place via a nozzle on the circumference of the drum.

Our ball mills are also available in an explosion-proof version (AETX).

Further product features:

- Drive power and speed according to customer process

- Filling/draining opening adapted to customer process

- Variable speed (optional)

- Wear protection or application-specific coating for the drum (optional)

- Control / degree of automation according to customer requirements

Protective fence around the ball mill on request

Standard ball mill for 600 kg of ground material.

Other sizes and configurations tailored to your individual processes on request.

* Dry grinding processes on request.